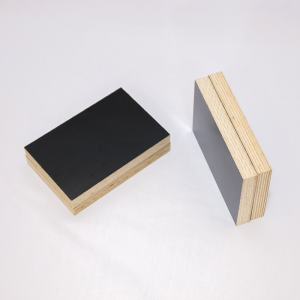

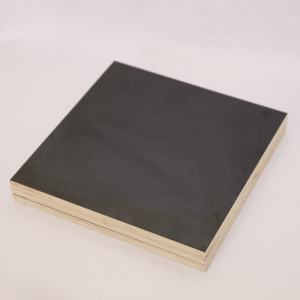

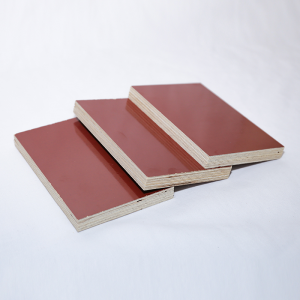

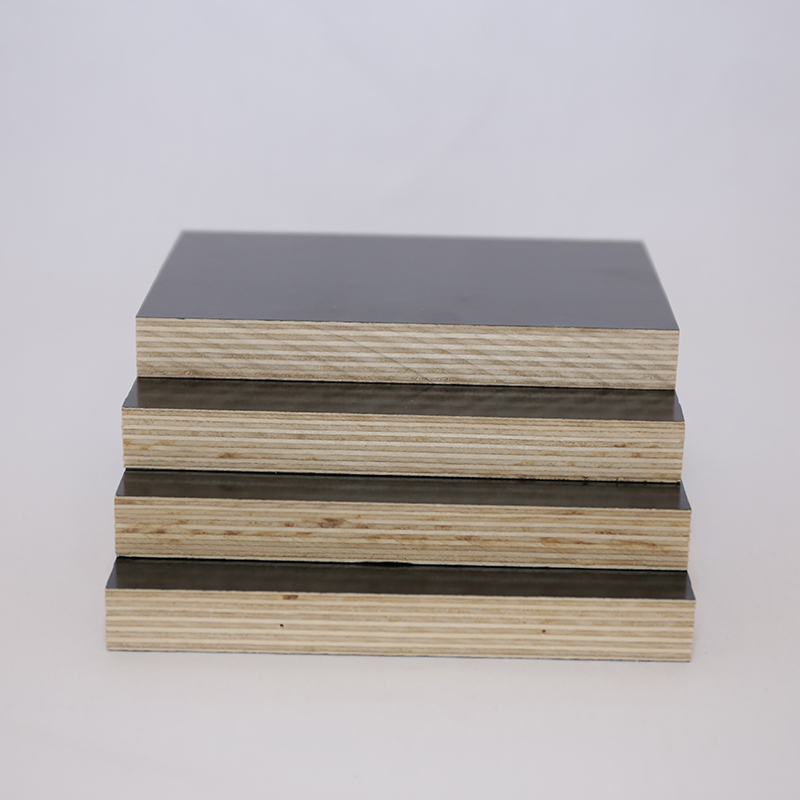

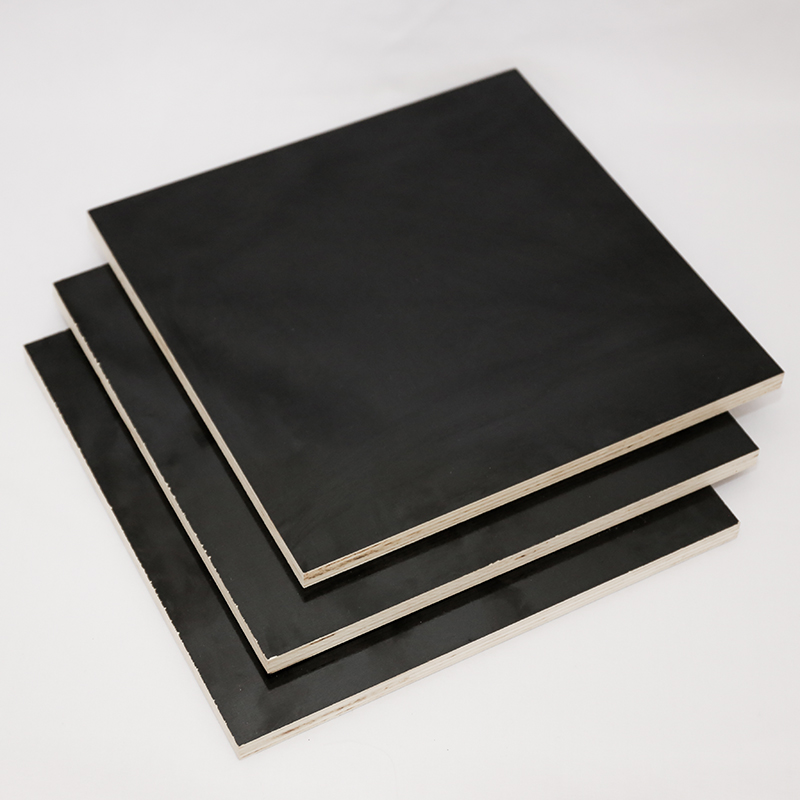

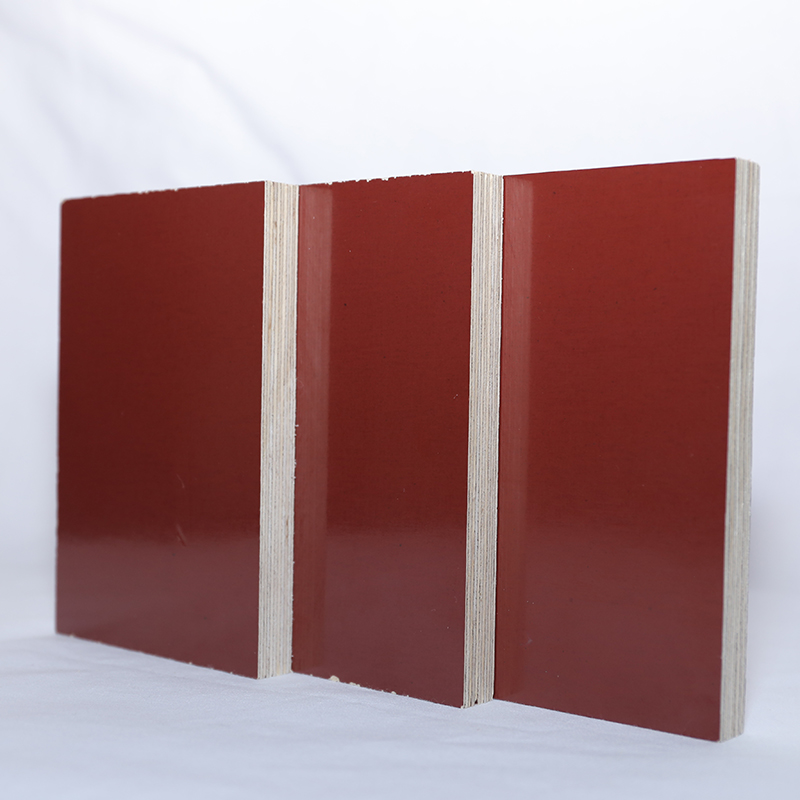

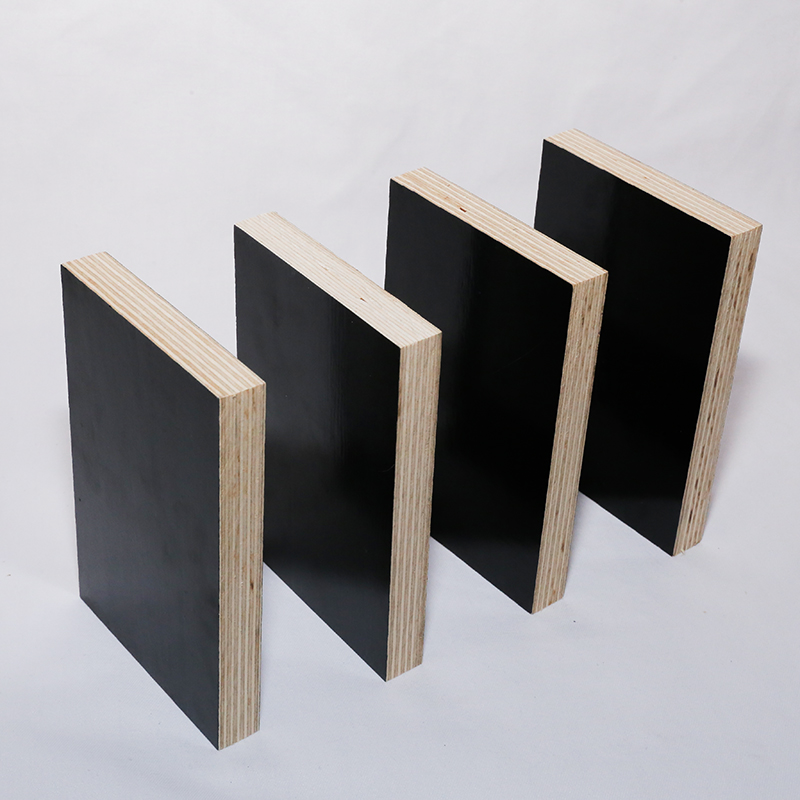

Architectural phenolic film-coated panels suitable for various construction projects

Specifications of building formwork

1. The main specifications are: 915x1830mm, 1220x2440mm, 1250x2500mm

2. Thickness: 9mm, 12mm, 15mm, 18mm, 21mm, 24mm...

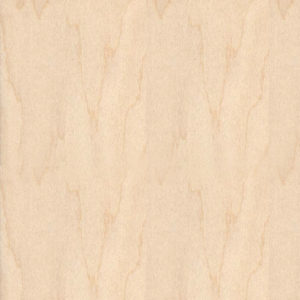

3. Material: poplar, birch, hardwood, pine, mixed wood, etc.

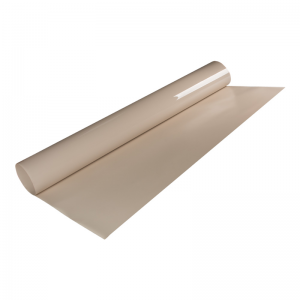

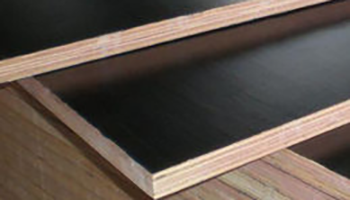

4. Glue species: phenolic glue, melamine glue, urine glue

5. Film paper: phenolic coated paper brown film, black film

Product Standars

| Number | Project | Product Standards | |

| 01 | edge defect | none | |

| 02 | Glue opening, cracking, layering | none | |

| 03 | length tolerance | ±3mm | |

| 04 | Thickness tolerance | 12±0.2mm/15±0.2mm/18±0.5mm | |

| 05 | Diagonal tolerance | ±3mm | |

| 06 | Warpage | no more than 1% | |

| 07 | Surface dents, indentations, bulges | none(Allows for individual slight indentations) | |

| 08 | surface repair | none | |

| 09 | Surface scratches, burns, burrs | none(Allows for individual slight indentations) | |

| 10 | Laminated paper is glued, damaged, and missing edges | none | |

| 11 | discoloration | none | |

| 12 | Panel stitching seam | none | |

| 13 | Panel Lamination | none | |

| 14 | patch, patch | none | |

| 15 | moisture content | 6~8 | |

| 16 | bond strength Mpa | The ratio of qualified specimens to the total number of valid specimens is ≥90% | ≥0.7 |

| 17 | Timber damage rate 39% | ||

| 18 | Static bending strength Mpa | along the grain≥45 | |

| 19 | horizontal stripes≥30 | ||

| 20 | Elastic Modulus | along the grain≥6000 | |

| 21 | horizontal stripes≥4500 | ||

Light Weight

More suitable for high-rise buildings and bridge construction.

LargeFormat

The maximum format is 2440×1220mm, which reduces the number of joints and improves the working efficiency of the formwork.

Long Lasting

No warping, no deformation, no cracking, good water resistance, high turnover and long service life.

Easy Demoulding

The demoulding is easy, only 1/7 of the steel mold.

Concrete Pouring

The surface of the poured object is smooth and beautiful, minus the secondary plastering process of the wall, it can be directly veneered for decoration, reducing the construction period by 30%.

Corrosion resistance, good thermal insulation performance

Does not pollute the concrete surface; conducive to winter construction.

Good construction performance

The performance of nailing, sawing and drilling is better than that of bamboo plywood and small steel plates. It can be processed into various shapes of formwork according to the construction needs, and the formwork of the curved plane.

Used many times

It can be used repeatedly if stored and used correctly.

Four advantages to achieve brand reputation and help high-quality projects

You have finally found a powerful faction, choose Chunsen, choose assured quality

1. Rich production experience

The company has many years of industry experience and a number of professional technicians. The company adheres to the principle of quality first, and its products are sold at home and abroad. It is a modern enterprise integrating processing, production and sales services.

Years of industry experience, a complete range of products.

2. Product strength

Strictly select and use high-quality raw materials and accessories to ensure that each product is born with high quality from the beginning of production.

The board surface is flat and smooth, with light weight, no warping, no deformation, no cracking, easy demoulding, high strength, good bonding force and nail holding force to ensure the use effect.

High water resistance and thermal insulation performance, large plate surface, high cycle turnover and durable use.

Template source factory direct sales, cost-effective, quality assurance.

3. Production strength

20 acres of product production base, standardized modern production workshop, 5 million / year clear water template production and manufacturing capacity.

Specializing in quality, we have advanced plywood manufacturing and processing equipment production lines at home and abroad.

Professional focus, research and development customized production integrated manufacturers

4. Quality assurance

Carefully select the raw material supply, enter the factory and then pass the screening, and control the product quality from the source.

The whole process of inspection procedures is perfect, the indicators are harsh, and it fully conforms to the national inspection and testing standards and environmental protection certification.

The formwork has been tested by the National Supervision and Inspection Center and has reached B/T1756-2008 "Standard of Plywood for Concrete" and has been praised and praised by many parties.

Strict quality control, proficient in details, whole-process inspection, after-sales guarantee.